Main Benefits:

Additional Information:

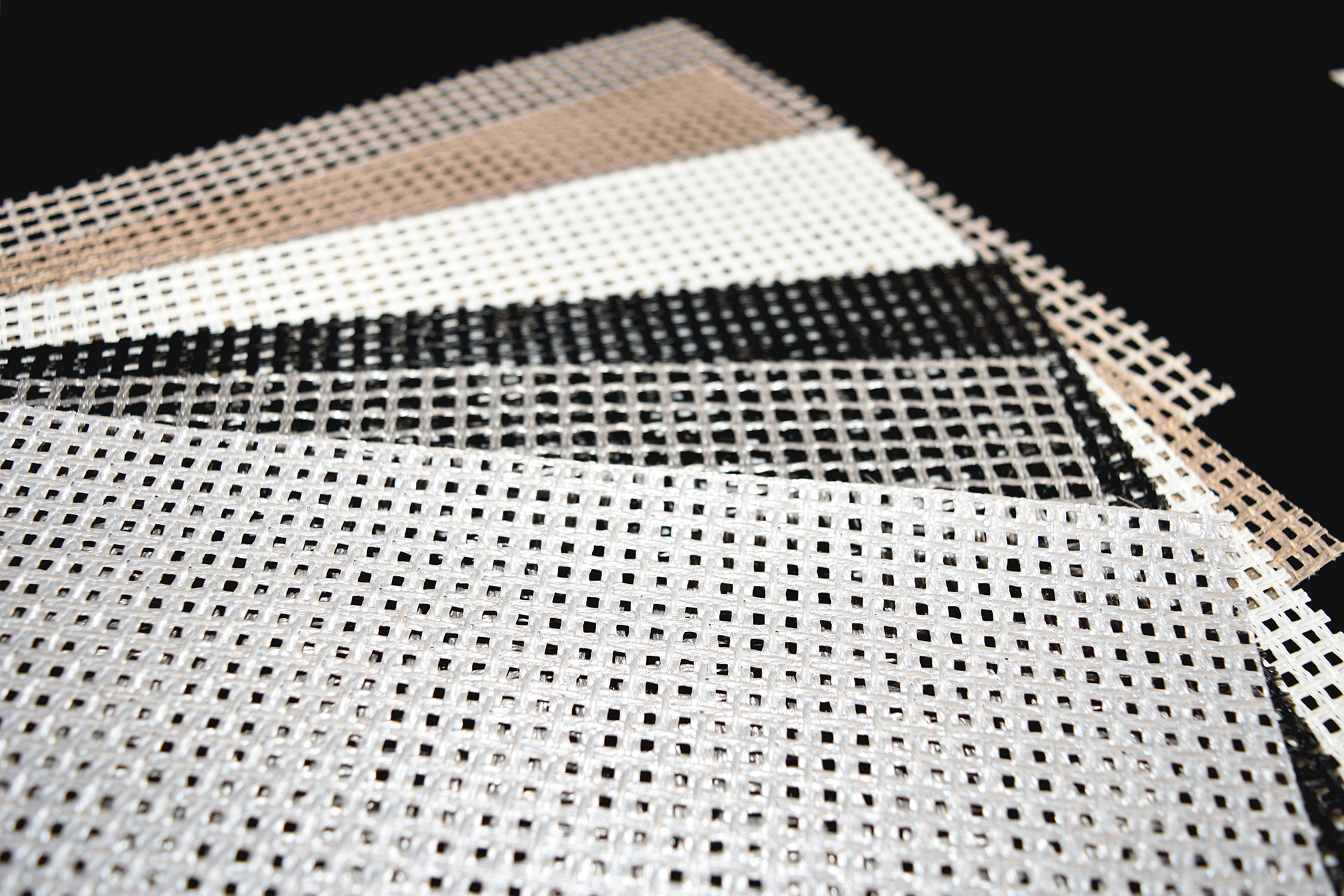

What is PTFE Fiberglass Mesh:

Polytetrafluoroethylene (PTFE) coated fiberglass ventilated fabric mesh is the most durable fabric on the market. PTFE coated fiberglass provides uncompromised and unequaled beauty, longevity, and functionality. PTFE was developed in 1938 and has been used in building applications since the 1970s. PTFE coating is very slick, and nothing sticks to the surface making an ideal surface that is self-cleaning with rainwater.

Main Benefits:

Additional Information:

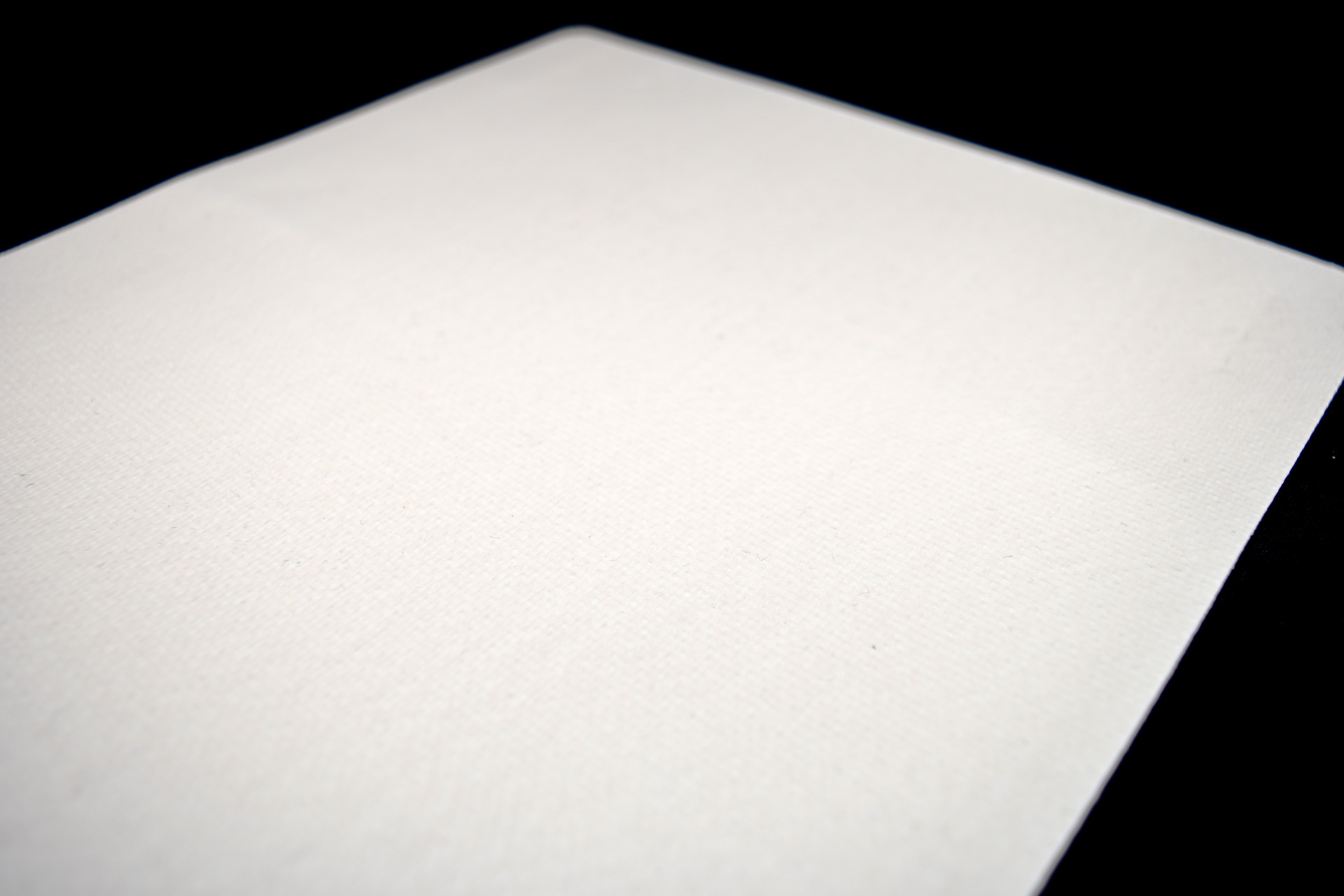

What is PTFE Fiberglass Membrane:

Polytetrafluoroethylene (PTFE) coated fiberglass non-ventilated fabric is a membrane and the most durable fabric on the market. PTFE coated fiberglass provides uncompromised and unequaled beauty, longevity, and functionality. PTFE was developed in 1938 and has been used in building applications since the 1970s. PTFE coating is very slick, and nothing sticks to the surface making an ideal surface that is self-cleaning with rainwat

Main Benefits:

Additional Information:

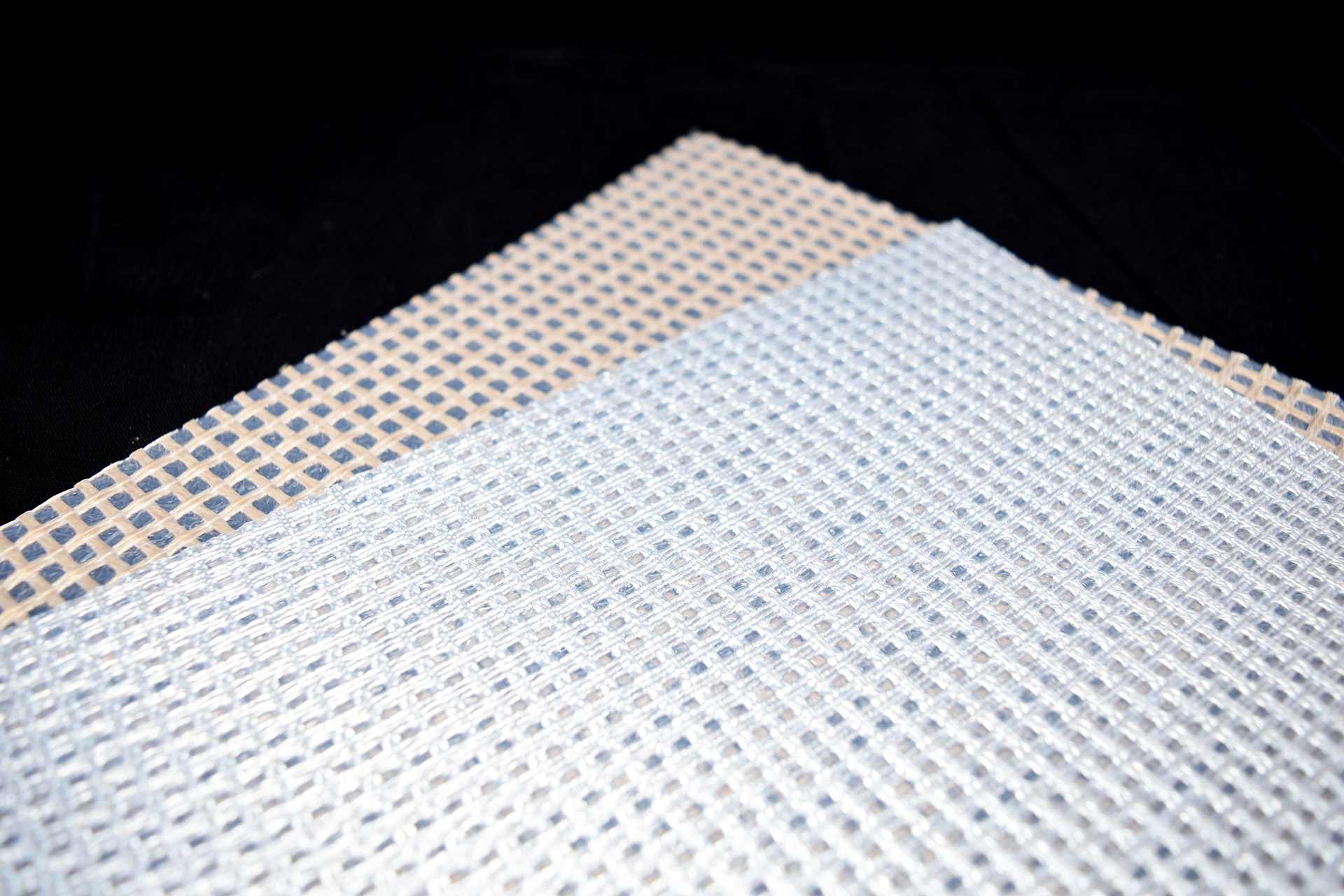

What is Laminated PTFE Fiberglass Membrane:

Polytetrafluoroethylene (PTFE) coated fiberglass mesh fabric with an added waterproof clear laminated film creating a very unique, highly translucent membrane that is extremely durable.

The five-story, 60’s era West Hills Medical Office Building in Los Angeles was due for an exterior facelift. A complete exterior renovation by Michael W. Folonis Architects revealed that water infiltration had caused structural damage to the existing horizontal plaster awnings; removing them was a costly process that consumed much of the project budget. This […]

We are pleased to have collaborated with KieranTimberlake and the outfit of a parking structure on the Rice University Campus. In their blog post, they describe the concepts they employed to create an iconic sculptural element. For more details see the KieranTimberlake blog post.