Main Benefits:

Additional Information:

What is What Is ETFE (Foil/Film):

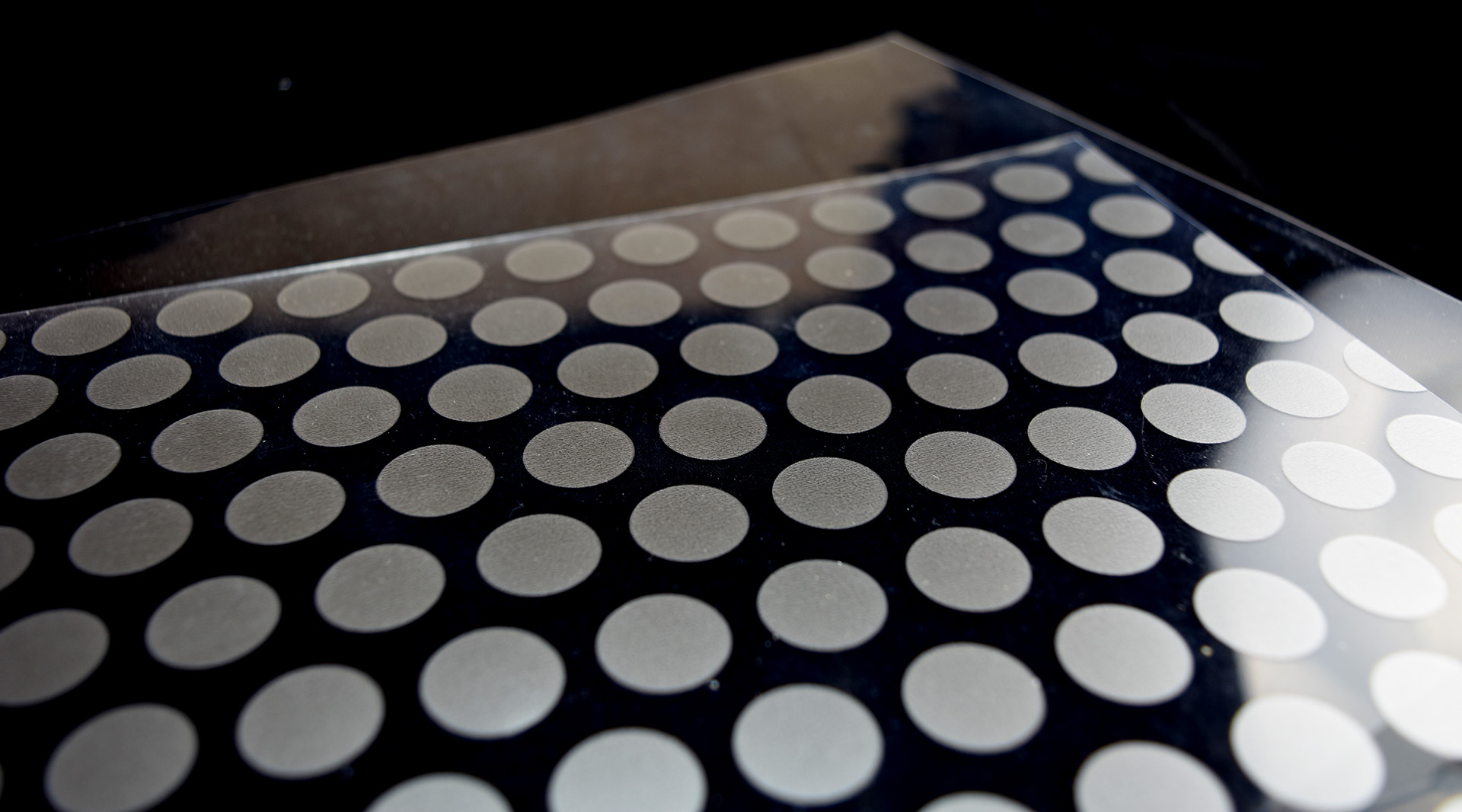

Ethylene Tetrafluoroethylene (ETFE) is a fluorine-based plastic polymer that offers a creative and lightweight alternative to glass. Developed over 40 years ago, ETFE has a similar light transmission to glass, but at just 1% of the weight. With a lifespan of over 30 years and excellent weathering properties, ETFE film is becoming the material of choice for outdoor and outdoor/indoor spaces in a variety of climates.

The five-story, 60’s era West Hills Medical Office Building in Los Angeles was due for an exterior facelift. A complete exterior renovation by Michael W. Folonis Architects revealed that water infiltration had caused structural damage to the existing horizontal plaster awnings; removing them was a costly process that consumed much of the project budget. This […]

We are pleased to have collaborated with KieranTimberlake and the outfit of a parking structure on the Rice University Campus. In their blog post, they describe the concepts they employed to create an iconic sculptural element. For more details see the KieranTimberlake blog post.