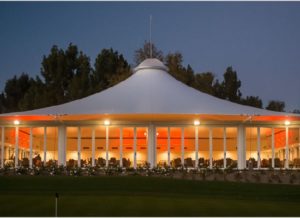

Located in Palm Springs, California, Indian Wells Tennis Garden is home to the third-largest tennis stadium in the world. In preparation for hosting the BNP Paribas Open, the world’s fifth-largest tennis tournament, the owners wanted to install a shade canopy to protect viewers from the desert heat and perpetual sun. The canopy also needed to be lightweight, low-impact on the site, and fully installed within five months in order to be ready for opening day.

STRUCTURFLEX’S CONCEPTS

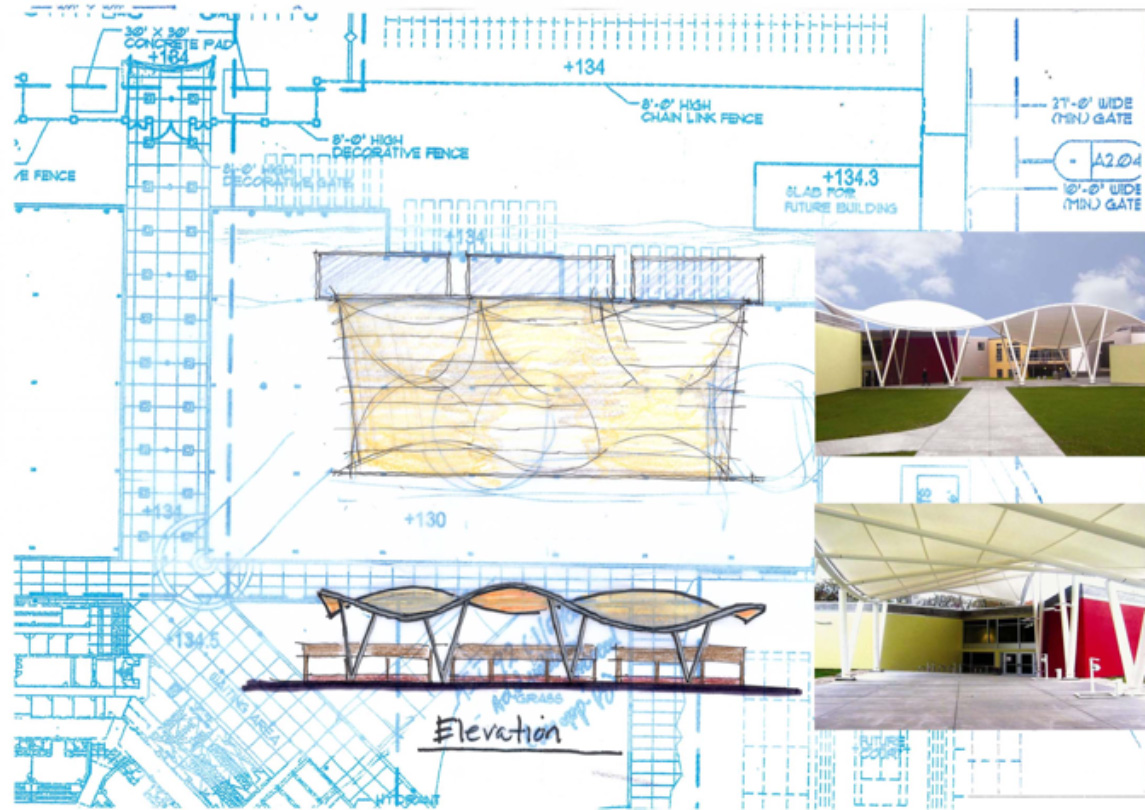

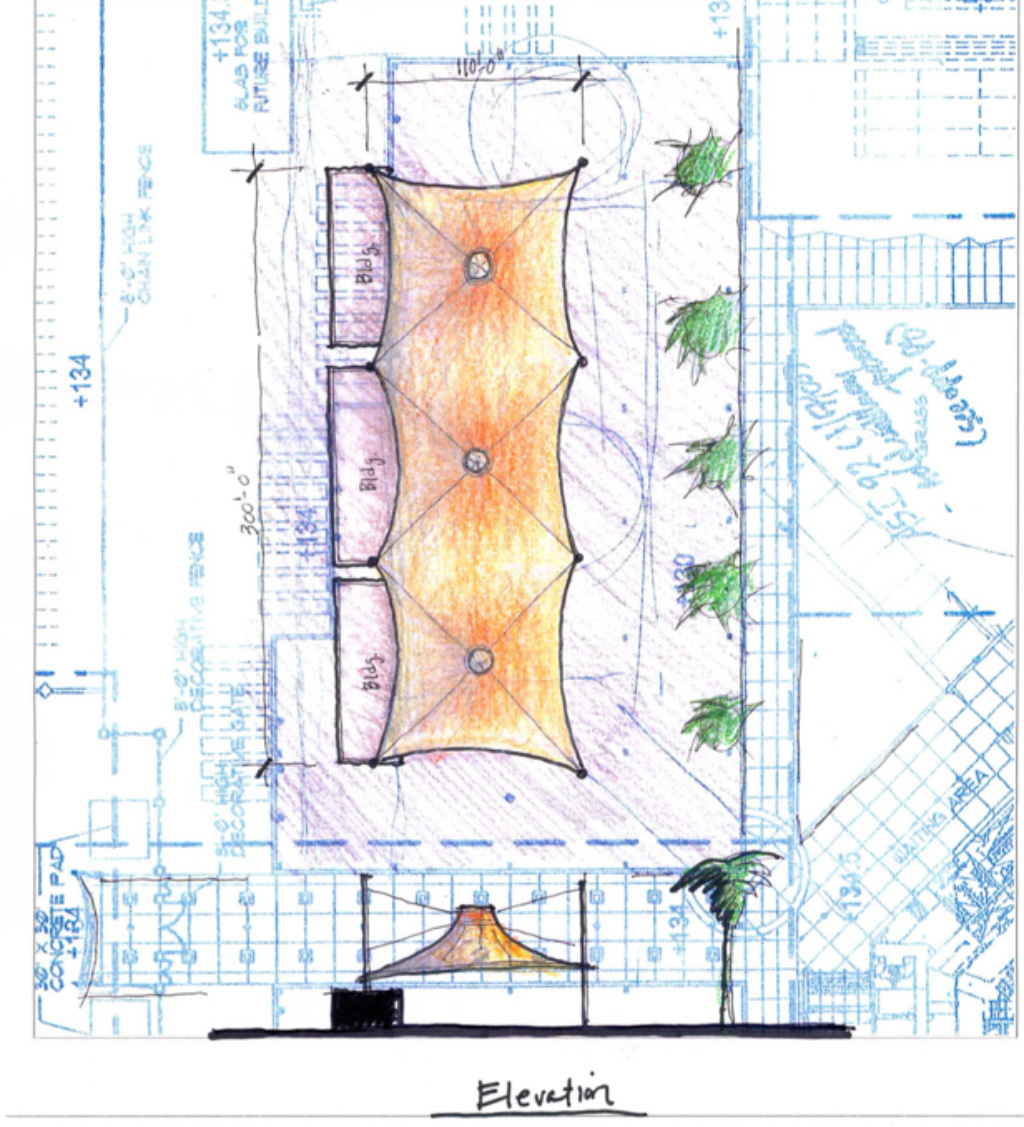

We know how architects work and create, and because of our years of experience, we are able to translate architectural ideas in any form into buildable forms. The Indian Wells Tennis Garden pavilion started as napkin sketches, and Structurflex transformed these hand-drawn concepts into design documents.

RENDERING

The next part of our process is creating renderings that depict what a project will actually look like. This allows the architect and the client to visualize the finished product and confirm that the design is what was intended.

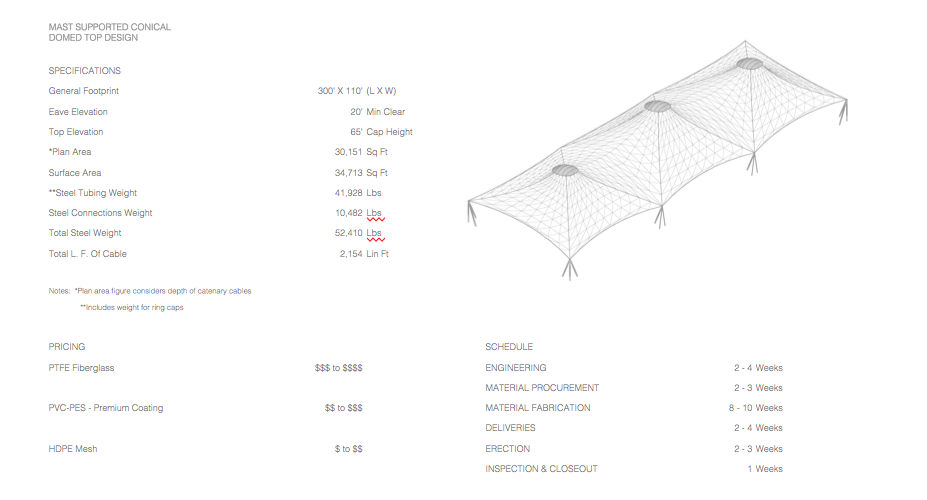

BUDGETING

SITE & SHADE STUDIES

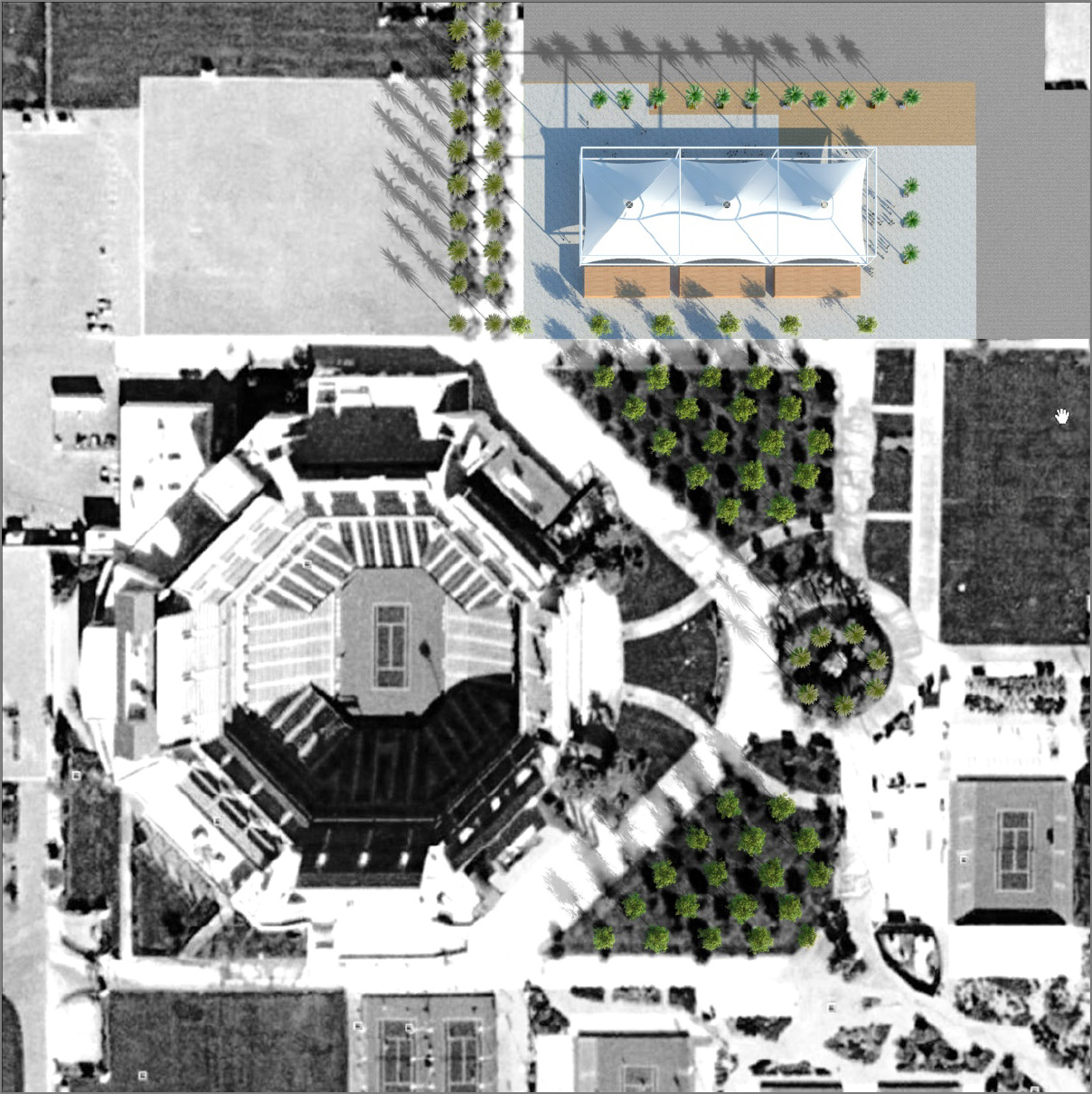

Indian Wells Tennis Garden is sited in Palm Springs, which is sunny an average of 350 days per year. This presented a unique challenge: create a structure that provides almost year-round sun coverage without impacting the site. We conducted site and shade studies to assess the correct size, shape and placement of the canopy to provide the desired protection.

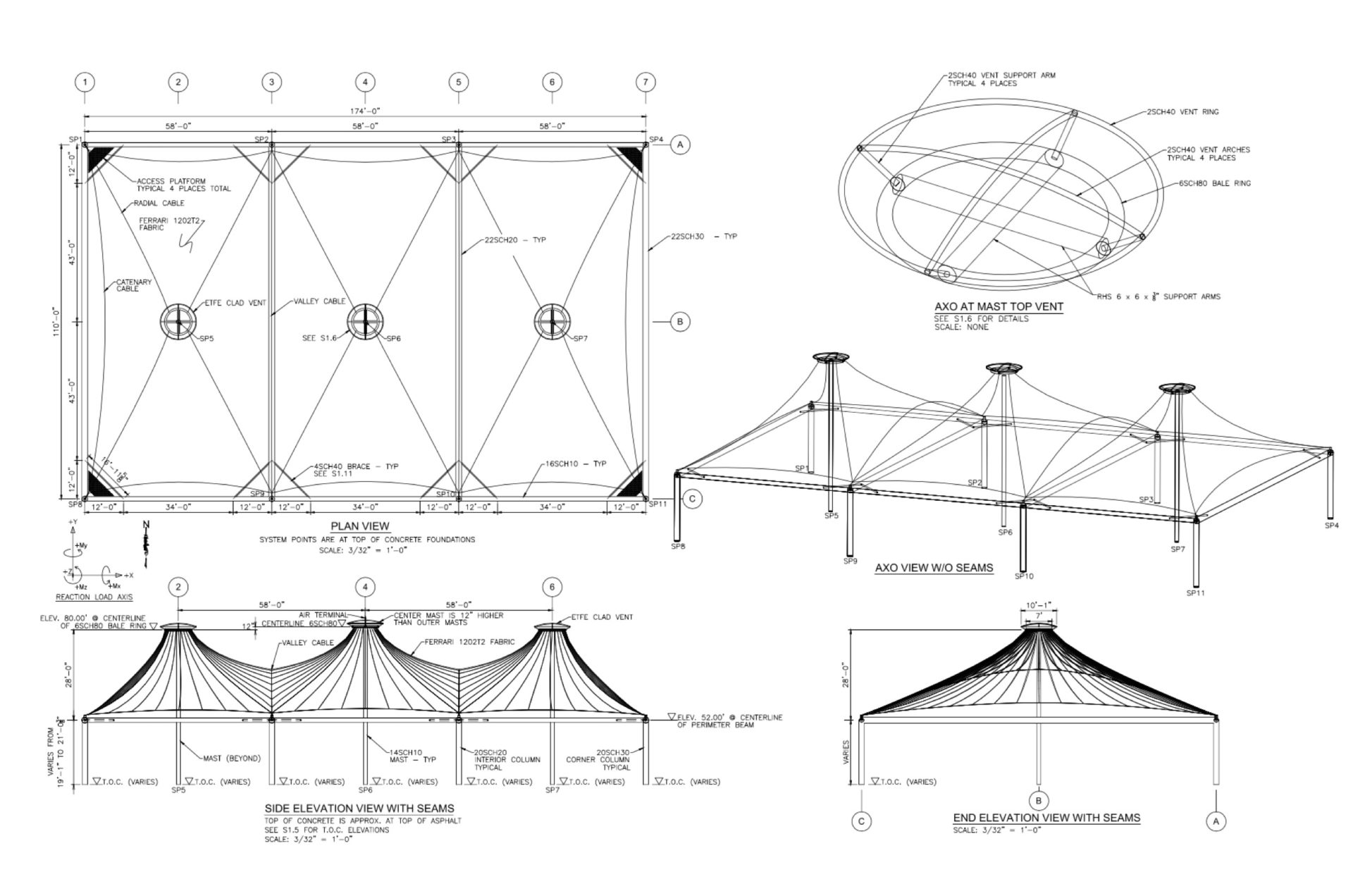

DESIGN DEVELOPMENT

A coated PES tensile membrane structure was selected to provide an elegant yet affordable solution. The tensile membrane was designed to be installed in a specific pattern to create an aesthetically pleasing exterior view.

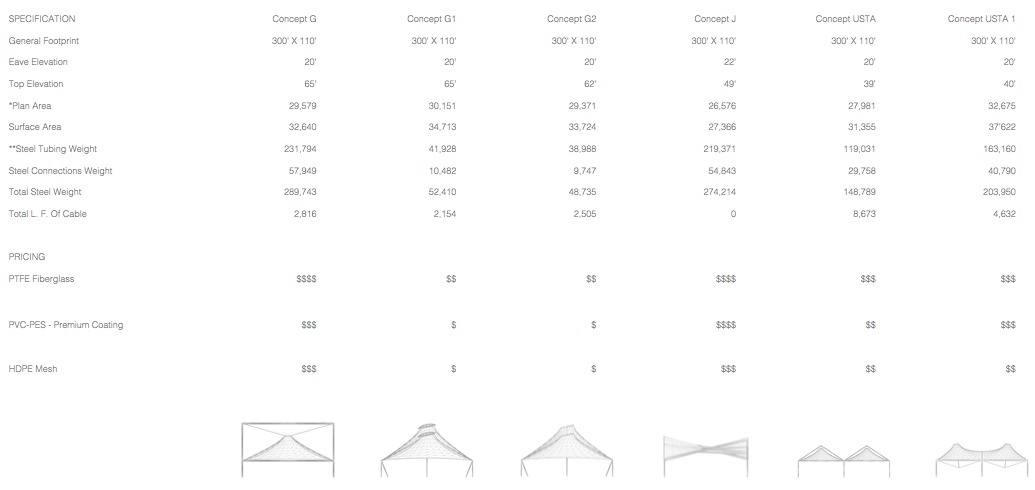

PRICING ANALYSIS

One of the benefits of working with Structurflex is that we not only provide design and design assistance, but we also provide engineering services. Structurflex produced the final engineering documents for the Indian Wells Tennis Garden design. We used single tube sections of steel for support, rather than complex trusses that would detract from the clean simplicity of the long spans the architect envisioned. We incorporated ETFE caps that were slightly raised above the rings, to allow heat to rise and escape.

We fabricated the tensile canopy. Currently Structurflex has operations in five countries, including the United States, and we serve countries around the world. We also engineered, supplied, and installed all structural steel.

We have installation crews all over the world so that each project is installed correctly. We coordinated with the general contractor and sub-trades to install the membrane on time, within the five-month window.

The five-story, 60’s era West Hills Medical Office Building in Los Angeles was due for an exterior facelift. A complete exterior renovation by Michael W. Folonis Architects revealed that water infiltration had caused structural damage to the existing horizontal plaster awnings; removing them was a costly process that consumed much of the project budget. This […]

We are pleased to have collaborated with KieranTimberlake and the outfit of a parking structure on the Rice University Campus. In their blog post, they describe the concepts they employed to create an iconic sculptural element. For more details see the KieranTimberlake blog post.